Services

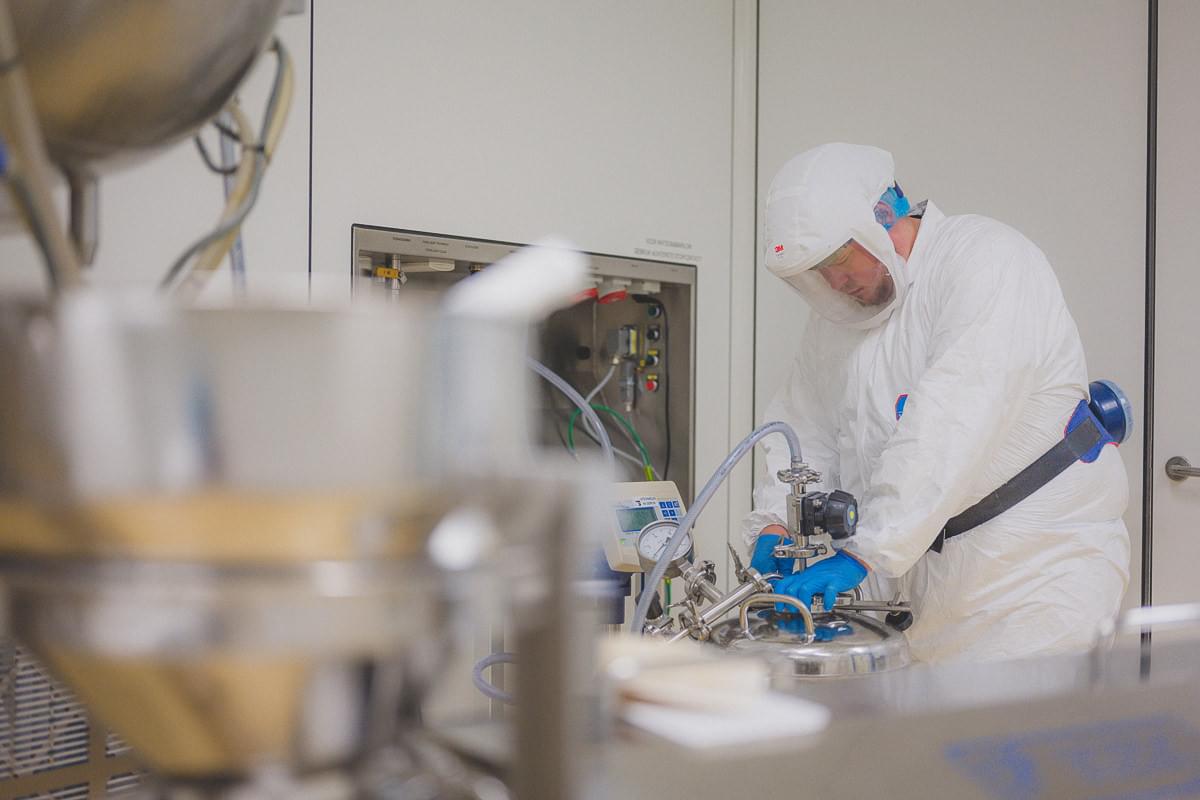

Sanico is Europees marktleider in productie en verpakking van niet-steriele farmaceutische producten in alle galenische vormen.

We bieden daarin een full service dienstverlening, gaande van de begeleiding van de nodige interfaces en ontwikkeling van het artwork tot de productie en verpakking van het afgewerkte product, inclusief de release voor de internationale markten.

Onze eigen cocktail bestaat uit operational excellence in combinatie met de meest gesofisticeerde uitrusting en hoogst competente medewerkers.

---103-original.jpg)